Rooted in History

Our company traces its roots back nearly a century, stretching back to the days of the Great Depression when Herbert Hoover was President. Since our early beginnings, we have been dedicated to the craft of transforming natural ingredients into the highest quality organic fertilizers. This proud tradition began with our founder H.G. Sanders in 1929 and continues today through his great grandchildren. His knowledge and expertise have been handed down from generation to generation and helped define the organic garden for over 95 years.

A Family Tradition

If you’re an Espoma Organic gardener, you’re in good company. Maybe your mom, aunt or grandfather was an Espoma gardener too. Espoma is a tradition that many families share, and for good reason – our products have over nine decades of proven results and have claimed their rightful places among the best-selling organic fertilizers of all time. Refined and developed for nearly a century, they are classic, timeless, and built on a heritage of passion, dedication, and innovation.

We’re Still Growing

Today we are proud to be the original and largest manufacturer of organic fertilizers in the lawn and garden industry. We have provided nearly a century of gardening joy to our customers and we’re still growing strong. We remain committed to championing organic gardening, educating people about the power growing a garden can have to uplift others, and inspiring people to express themselves through the beauty of gardening.

4th Generation Family Owned Since 1929

H.G. Sanders

Founder Herbert G. Sanders grew up on a small farm in southern NJ. He started our company in 1929 with one fertilizer called Espoma Organic. In 1946 he transformed the company by creating it’s #1 product Holly-tone.

Dean Sanders

After graduating from Lafayette College and serving in the Army, H.G’s son Dean joined Espoma in 1953. He expanded the Tone family of products and began automating its facilities to keep up with growth.

Serge Brunner

After graduating from Brown University and getting his PhD from the University of Pennsylvania, Dean’s nephew Serge joined Espoma in 1977. Serge computerized the company, and further automated and expanded the operation.

Jeremy Brunner

After graduating from Cornell University and getting his law degree from Rutgers University, Serge’s son Jeremy joined Espoma in 1997. Jeremy expanded the distribution nationwide, and added new product lines.

Headquarters

Green Office Facility

- Oxygen producing & water efficient living green wall

- Solar field serves as energy source

- LED high-efficiency lighting

- Energy star-rated cool roofing

- Hyper-heating Inverter technology heat pumps (low energy consumption)

Manufacturing

Millville NJ

Manufacturing and Headquarters since 1929

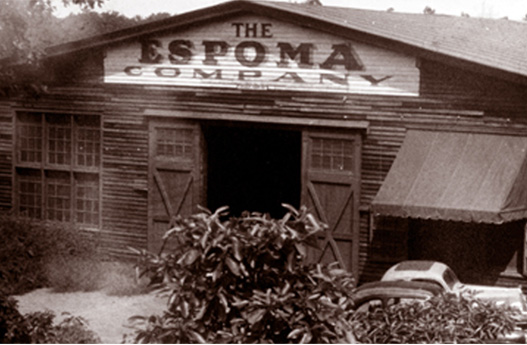

Espoma began its manufacturing in 1929, made manually, in a small wooden building with a blend of nearby natural materials in Millville, NJ. When that plant burned down in 1946, it was replaced when the community rallied to save the company and a new building was erected for manufacturing.

Since then six new warehouses have been manufactured for finished goods storage, two for raw goods storage and a state-of-the-art manufacturing plant that is capable of fill 8 bags per minute to meet demand.

| Building | Function | Year Built |

|---|---|---|

| 1 | Production – 2 lines for 20 – 50 lb. bags | 1946 |

| 2 | Finished Goods Warehousing | 1957 |

| 3 | Finished Goods Warehousing | 1962 |

| 4 | Raw Material Warehousing | 1965 |

| 5 | Finished Goods Warehousing | 1969 |

| 6 | Raw Material Warehousing | 1977 |

| 7 | Finished Goods Warehousing | 1987 |

| 8 | Finished Goods Warehousing | 1992 |

| 9 | Production – Bags less than 10 lbs and liquids | 1996 |

| 10 | Finished Goods Warehousing | 2009 |

Hegins, PA

New 60,000 sq. ft. Facility in Hegins, PA.

Espoma has constructed a new 60,000 sq. ft. facility in Hegins PA to meet the growing demand for Espoma Products. The new facility has the capacity to produce 260m lbs/yr of product with the ability to shop in bulk truckloads or totes.

The new plant will ensure the company as ample capacity for future growth and will help control costs so we can provide optimum value to our customers.